An air compressor is one of the most useful tools that there is in a garage or workshop. Air compressors "run" cool and are very durable. Most of all, air compressors are incredibly versatile, as they can be used for so much more than simply inflating tires. With the addition of a quick connect coupler, an air compressor can power a multitude of tools used in home improvement and automotive work. Here are a few of the more common attachments that are powered by an air compressor:

Air Nail Gun. Useful especially in roofing projects, the compressor provides dependable, significant power to drive nails.

Air Stapler. Similar to the nail gun, an air stapler is used for smaller, more delicate jobs. One of the most effective areas to use a stapler is in laying carpeting, but a stapler is also handy in upholstery work, some carpentry work, and other general home repair projects.

Air Sander. For large scale sanding jobs, an air sander provides the needed power to get the job done. Cars (paint), hard wood floors, and drywall are a few such uses.

Air Spray Gun. Painting jobs take just a fraction of a time with an air spray gun. In addition to cutting painting time, there is less set up and clean up involved when you don't have to worry about brushes, rollers, and pans.

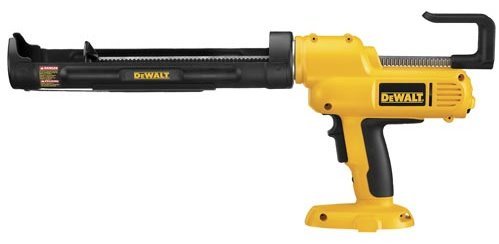

Air Caulking Gun. Using an air caulking gun provides a more consistent level of pressure than a hand powered gun offers, thus, enabling you to do more quality work.

Air Hammer/Chisel. These tools are used for shaping, plenishing, and scoring.

Air Sandblaster. This is useful for refinishing cars or preparing surfaces for painting.

Air Ratchet Wrench. This tool is most helpful in automotive projects, providing the much needed power that manual labor cannot provide, especially in tight spots.

Air Drill. The power behind an air drill makes drilling virtually effortless. This is especially helpful in drilling into hard materials such as concrete.

With the many varied uses for a compressor, it is of the utmost importance that the machine be kept in good working condition. Be sure to clean the machine after every use. Replace broken or significantly worn parts with Ingersoll Rand compressor parts. Make sure your compressor filter is clean, and replace it as needed with a new air compressor filter. You may want to keep extra air compressor filters on hand, along with other Ingersoll Rand compressor parts in case something were to break while you are in the middle of a job.

While air compressors are incredibly useful, they can also be potentially dangerous. Strict safety measures must be taken when operating an air compressor, along with its various attachments. Since an air compressor is so versatile, there are a lot of different attachments that all have different safety precautions that must be taken. Each attachment releases the power stored in the machine a different way, and some can be deadly if mishandled. Be sure to consult your operator's manual for safe handling, usage, and maintenance.

| Price :

| Price :